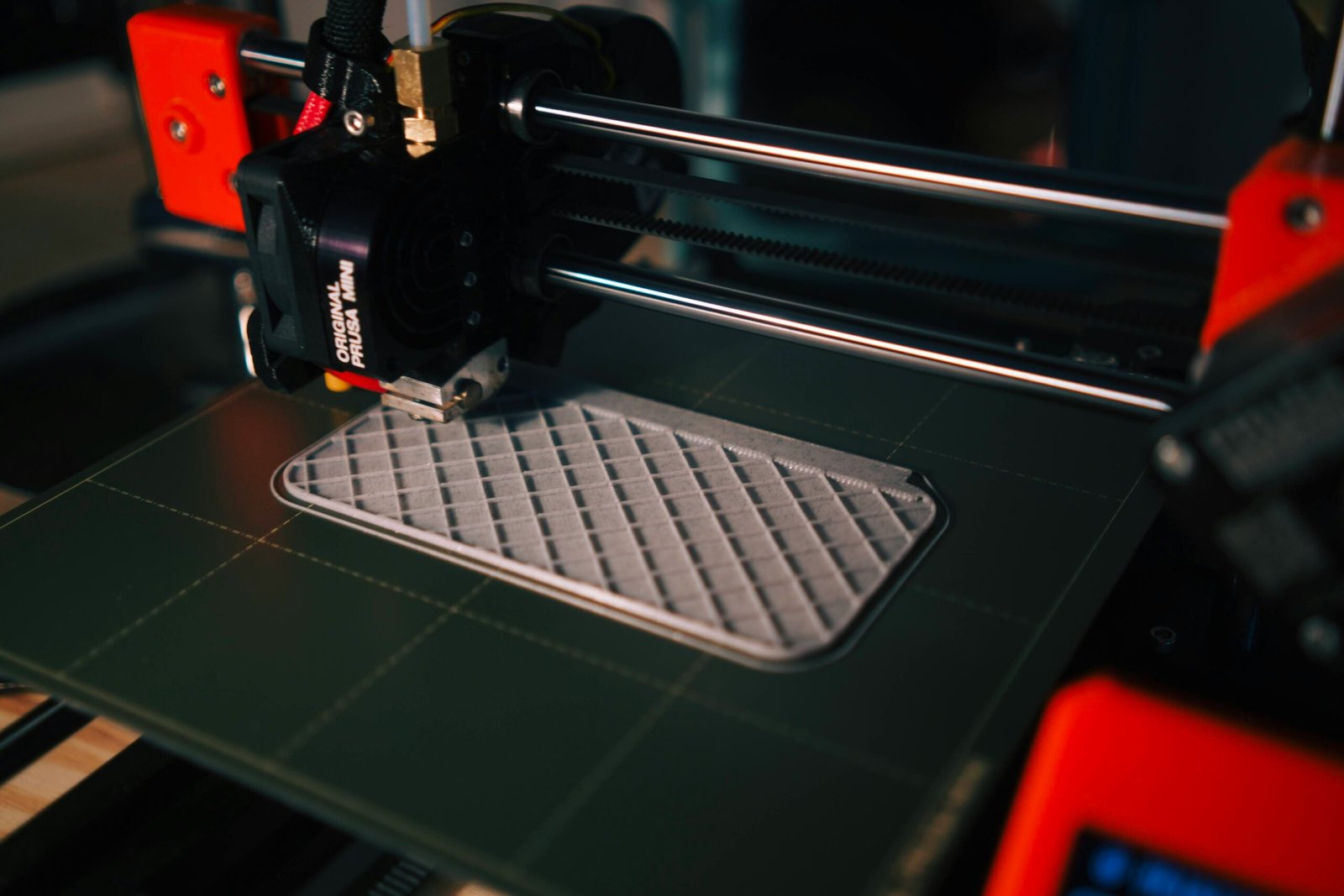

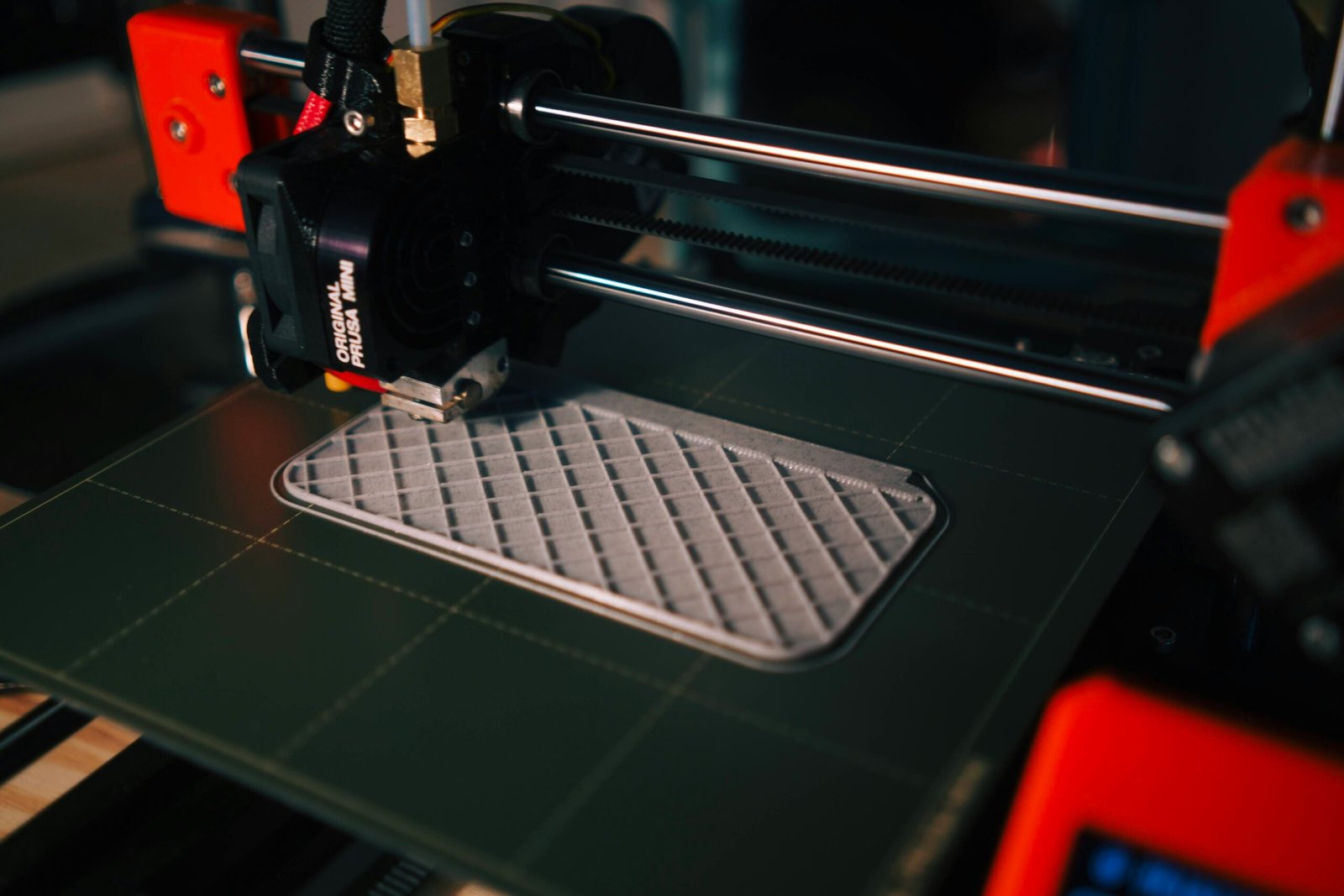

One of the key ways in which 3D printing is transforming the fashion industry is through its ability to create intricate and complex designs that were previously impossible to achieve through traditional manufacturing methods. With 3D printing, designers can now bring their wildest imaginations to life, pushing the boundaries of what is considered possible in fashion.

For example, designers can create garments with intricate patterns and textures that would be extremely difficult, if not impossible, to achieve using traditional sewing techniques. With 3D printing, these patterns can be precisely and flawlessly reproduced, resulting in garments that are truly unique and eye-catching.

Furthermore, 3D printing allows for the creation of customized products, tailored specifically to an individual’s body shape and size. This is a game-changer for the fashion industry, as it eliminates the need for standard sizing and mass production. Instead, garments can be created on-demand, ensuring a perfect fit every time.

In addition to its design capabilities, 3D printing also offers significant advantages in terms of sustainability. Traditional fashion manufacturing processes often result in a significant amount of waste, as fabric is cut and discarded to create garments. With 3D printing, however, the amount of waste can be dramatically reduced, as garments are built layer by layer, using only the necessary amount of material.

Moreover, 3D printing allows for the use of sustainable materials, such as biodegradable plastics and recycled fibers. This not only reduces the environmental impact of fashion production but also opens up new possibilities for creating eco-friendly and ethically sourced garments.

Overall, the impact of 3D printing on the fashion industry is profound. It is revolutionizing the way garments are designed and manufactured, offering endless possibilities for creativity and customization. Furthermore, it is paving the way for a more sustainable and ethical fashion industry, where waste is minimized, and materials are responsibly sourced. In the following sections, we will delve deeper into the specific applications of 3D printing in fashion, exploring how it is being used by designers and brands to create innovative and groundbreaking designs.

Moreover, 3D printing has the potential to revolutionize the supply chain in the fashion industry. With traditional manufacturing processes, garments are typically produced in large quantities and then distributed to various retailers. This often leads to overproduction and excess inventory, as it is difficult to accurately predict consumer demand.

However, with 3D printing, garments can be produced on-demand, eliminating the need for mass production and reducing the risk of overstock. This not only allows for a more efficient use of resources but also reduces the environmental impact of the fashion industry. By producing garments only when they are needed, 3D printing helps to minimize waste and decrease the carbon footprint associated with manufacturing and transportation.

Furthermore, 3D printing opens up new possibilities for sustainable materials in fashion. Traditional manufacturing processes often rely on materials that are harmful to the environment, such as synthetic fabrics and chemicals. In contrast, 3D printing allows for the use of eco-friendly materials, such as biodegradable plastics and recycled fibers.

In addition to its environmental benefits, 3D printing also has the potential to democratize fashion. In the past, the fashion industry has been known for its exclusivity, with high-end designers dictating the trends and styles. However, with 3D printing, anyone with access to a printer and design software can create their own unique garments.

This democratization of fashion not only promotes creativity and self-expression but also challenges the traditional power dynamics within the industry. It allows for a more diverse range of voices and perspectives to be heard, breaking down barriers and opening up opportunities for emerging designers and independent creators.

In conclusion, 3D printing is poised to have a significant impact on the manufacturing processes in the fashion industry. From reducing waste and enabling customization to revolutionizing the supply chain and promoting sustainability, the potential benefits are vast. As the technology continues to advance and become more accessible, we can expect to see even greater innovation and transformation in the way garments are designed, produced, and consumed.

Advancements in Design with 3D Printing

3D printing opens up a world of possibilities for fashion designers. It allows them to experiment with unconventional materials, shapes, and structures, pushing the boundaries of traditional fashion design. With 3D printing, designers can create unique and innovative pieces that stand out from the crowd.

One of the most exciting aspects of 3D printing in fashion design is the ability to create complex geometries and intricate details. Traditional manufacturing methods often struggle to reproduce intricate patterns and designs accurately. With 3D printing, designers can bring their wildest imaginations to life, creating garments that are true works of art.

Moreover, 3D printing enables designers to incorporate sustainability into their creations. By using biodegradable materials and reducing waste, 3D printed fashion pieces can contribute to a more sustainable and eco-friendly industry. This aligns with the growing demand for sustainable fashion and allows designers to make a positive impact on the environment.

Another advantage of 3D printing in fashion design is the ability to customize garments to individual body shapes and sizes. Traditional clothing sizes often fail to accommodate the diverse range of body types, leading to ill-fitting garments. With 3D printing, designers can create personalized clothing that perfectly fits the wearer’s measurements. This not only enhances comfort but also promotes body positivity and inclusivity in the fashion industry.

Furthermore, 3D printing offers designers the opportunity to optimize the production process. Traditional manufacturing methods require the creation of molds and prototypes, which can be time-consuming and costly. With 3D printing, designers can directly translate their digital designs into physical objects, eliminating the need for intermediate steps. This streamlined production process allows for faster turnaround times and reduces the overall cost of production.

Additionally, 3D printing allows for easy iteration and experimentation. Designers can quickly create multiple prototypes and make adjustments on the go, without the need to start from scratch each time. This iterative design process enables designers to refine their ideas and create the best possible outcome.

In conclusion, 3D printing has revolutionized the fashion industry by providing designers with new opportunities for creativity, sustainability, customization, and efficiency. As technology continues to advance, we can expect to see even more exciting developments in the field of 3D printed fashion.

Additionally, 3D printing has the potential to revolutionize the design process in the fashion industry. Designers can now create intricate and complex patterns that were previously impossible to achieve with traditional manufacturing methods. The freedom and flexibility offered by 3D printing allow designers to push the boundaries of creativity and create truly unique and avant-garde pieces.

Moreover, 3D printing technology enables designers to experiment with new textures, structures, and materials that were once considered unconventional in the fashion world. From flexible and lightweight fabrics to metallic and translucent materials, the possibilities are endless. This opens up a whole new realm of possibilities for designers to create garments that are not only visually stunning but also functional and comfortable to wear.

Furthermore, 3D printing can also offer cost savings in the long run. While the initial investment in 3D printers and materials may be higher, the ability to produce garments on-demand eliminates the need for large-scale inventory and reduces the risk of overproduction. This can help designers and brands minimize waste and optimize their production processes, leading to more sustainable and efficient operations.

As the technology continues to evolve, we can also expect advancements in the speed and efficiency of 3D printing. Currently, the process can be time-consuming, especially for larger and more complex garments. However, ongoing research and development are focused on improving print speed and resolution, which will make 3D printing even more viable for mass production in the fashion industry.

In conclusion, the future of 3D printing in the fashion industry is bright and full of potential. From personalized and sustainable fashion to innovative designs and cost savings, 3D printing is set to revolutionize the way we create, produce, and consume fashion. As the technology continues to advance, we can expect to see even more exciting developments that will shape the future of the fashion industry as a whole.